Obtaining Polymer-Grade Propylene by Low-Energy Size-Exclusion Adsorptive Separation Technology

Inventor (s) : Jing Li

Date Awarded: December 2019

Summary:

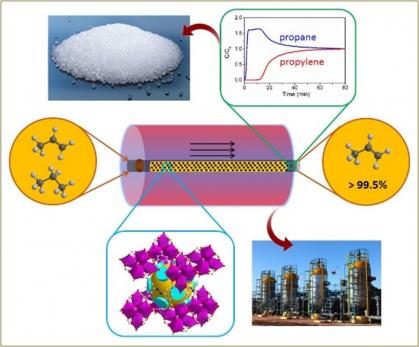

Olefin/paraffin separation, listed among the “seven chemical separations to change the world”, is of high commercial importance because high-purity olefins are required to comply “polymer-grade” specifications for the manufacture of plastics. Propylene is one of the most important olefins in petrochemical industry, primarily because of its use in the production of polypropylene, the world’s second most widely produced synthetic plastic. The propylene market was USD 75.4 billion in 2017 and projected to reach USD 99.17 billion by 2022. The continuous rise in global demand for polypropylene has resulted in an increasing need for polymer-grade (>99.5%) propylene. Nevertheless, the production of highly pure propylene represents a challenging and complicated process. Conventional separation of propylene relies on cryogenic distillation, which is a highly energy- and cost-intensive heat-driven process. The Rutgers TechAdvance project aims at addressing this issue by developing an alternative separation technology based on adsorptive separation which will significantly reduce the energy input and lower the cost associated with the generation of polymer-grade propylene.

Market applications:

- Scale-up production of MOF-based adsorbent materials

- Feedstock for manufacturing polypropylene

- Energy efficient separation technology for petrochemical industry

- High purity propylene for synthetic plastic industry