A "hard" and "crack-resistant" glass for functional applications

Inventor(s): Dr. Ashutosh Goel

Date Awarded: September 2020

Summary: The global bulletproof glass market is expected to reach $7.65 billion by 2022, with the North American market share of ~35%. The best performing materials for transparent armor are monocrystalline aluminum oxynitride (AlON) and sapphire (Al2O3). However, their high costs ($10 - $15 per square inch) and challenging manufacturability, prohibit their use in the practical applications. Due to these reasons, traditionally, the transparent armors have been made of transparent-elastomer inter-layered glass laminates.

The gasses used in the manufacturing of transparent armor, though inexpensive when compared with AlON or sapphire, exhibit significantly inferior elastic and mechanical properties than their crystalline analogs. This creates the need for a novel glass/glass-ceramic material that can bridge the gap by (i) exhibiting comparable optical but significantly superior elastic and mechanical properties than the commercial glasses being currently used, and (ii) being amenable to conventional manufacturing and processing techniques.

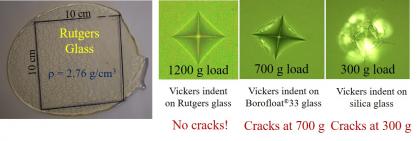

The glass being investigated in the framework of the TechAdvance grant (i) is transparent, (ii) can be synthesized by conventional manufacturing techniques, (iii) exhibits Vickers hardness = 7 – 8 GPa, Young’s modulus = 100 – 110 GPa, and (iv) does not crack at least until 1200 gf (11.8 N) Vickers load. The future work will focus on the scale-up, testing, and characterization of the developed glass composition for its further evaluation as a transparent armor material.

Market Applications:

- Transparent armor

- Cover glass for smartphones, electronic tablets and other electronic devices