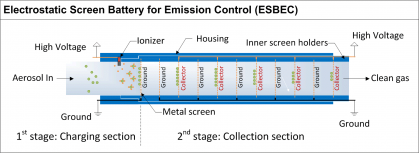

Continuing Development and Testing of the Electrostatic Battery for Emissions Control

Rutgers Inventor(s): Taewon Han; Gediminas Mainelis

Awarded: April 2020

Summary: Diesel engines are widely used in heavy-duty trucks, stationary engines, and power generators. However, diesel combustion engines emit substantial amounts of particulate matter (PM), a criteria pollutant. To control diesel particulate matter (DPM) emissions, diesel particulate filters (DPF) have been developed and implemented. However, the current DPFs have to be periodically regenerated to remove collected particles and are not very effective for capturing ultrafine (< 100 nm) particles which have been linked with negative health effects. Plus, they create backpressure resulting in loss of fuel efficiency.

Rutgers researchers Han and Mainelis have designed and developed an Electrostatic Screen Battery for Emission Control (ESBEC) for efficiently capturing even nano-sized DPMs from a variety of sources, such as diesel engines used in on-road mobile sources (e.g. cars, buses, trucks, etc.), non-road mobile sources (e.g. marine, locomotive, agricultural equipment, etc.), power generation equipment, etc. The ESBEC is an open channel device that uses an electrostatic collection mechanism to collect airborne DPMs on multiple sets of wire mesh screens coated with superhydrophobic material. Therefore, all collected particles can be simply washed-off without the need for thermal regeneration. Also, a used unit (i.e. sets of wire mesh screens) could be replaced with a clean unit – similar to replacing a battery. The major aim of this TechAdvance project is to advance the design, construction, and testing of ESBEC prototype to bring this technology closer to the market.

Market Applications:

- Mobile/stationary diesel market

- OEM/Retrofit market

- Other combustion related areas (e.g. furnaces, wood burners, electricity generation)